Research & Development

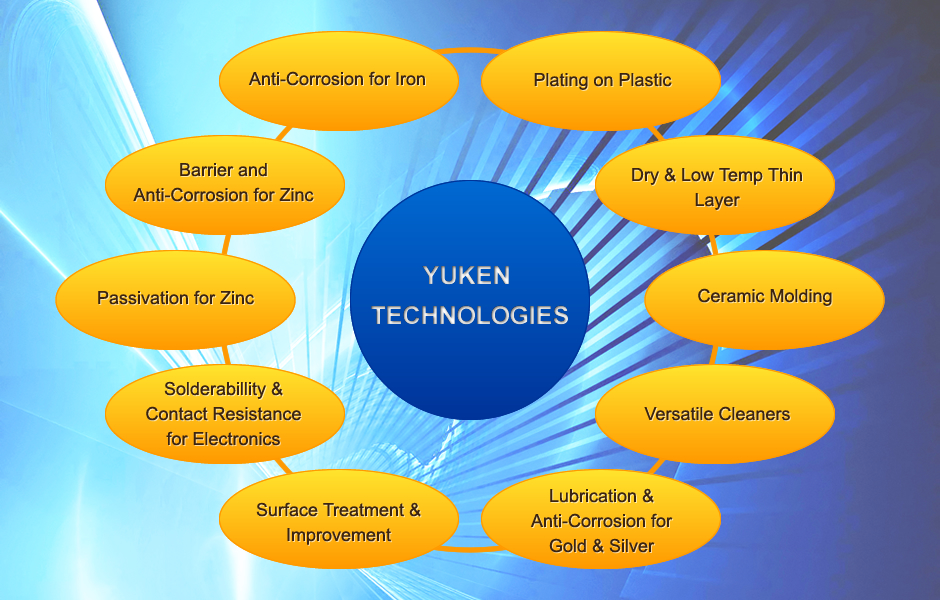

Since its establishment, YUKEN has been committed to its focus on research and development in the field of surface treatment.

As an innovation-oriented corporation, Yuken’s core management policy is the creation of highly innovative products. Strong product development is the reason why YUKEN is recognized as the leading company in the surface treatment market, and we continue to develop surface treatment products.

YUKEN industry, the core of the YUKEN Group, has the Technology Center (right building in photo) as the group’s center for all research and development. The Technology Center is a well-equipped facility conducting a range of work from fundamental research to applied technology research related to surface treatments.

These technologies are constantly being reviewed to align with the company's marketing policies in its commitment to provide top-tier customer services. YUKEN has gained recognition from business partners in major Japanese automotive and electronics OEMs.

Analysis Equipment (Available at YUKEN Industry)

YUKEN Industry owns test and analysis equipment to carry out product analysis and plating quality verification for customers.

Analysis equipment listed according to its usage

Click on a usage item to be directed to that analysis equipment accordingly.

- Torque measurement of bolts

- Measurement of solderability performance

- Other analysis and measurement instruments

- Analysis of plating defects and shortened service life of die casting

- Measurement of plated film thickness

- Analysis of on-site surface treatment solutions

- Corrosion test for plating

Torque measurement of bolts

Torque test apparatus

Friction coefficient measurement of bolts and other parts

Measurement of solderability performance

Solder checker

Evaluation of solderability performance (to determine the soldering quality)

Other analysis and measurement instruments

Photoelectron spectrometer (ESCA)

Analysis of constituents and status of surface chemical bonds (within 50nm)

Fluorescence X-ray analysis equipment (EDX)

Element analysis for RoHS and ELV compliance

UV visible spectrophotometer (UV meter)

Measurement of UV absorbed in the solution

Fourier Transform Infra-Red spectrophotometer (FT-IR)

Analysis of organic compounds

Gas chromatograph (FID, TD)

Separation and quantitative analysis of volatile substances

Atomic force microscope

3D inspection of surface contour at localized areas

X-ray diffraction equipment

Analysis of the crystalline structure of materials

Analysis of plating defects and shortened service life of die casting

Electron microscope (SEM, EDS)

Surface inspection, analysis of the material constituents (surface analysis, line analysis).

Color 3D surface profile measurement microscope with large depth of field

Alternate name: Laser microscope. Measurement and inspection of 3D surfaces, and surface roughness measurement.

Measurement of plated film thickness

X-ray fluorescence film thickness measurement instrument

Thickness measurement of plated film (such as Cu、Ni、Cr、Zn、Sn)

Small area fluorescence X-ray analysis instrument

Analysis of material constituents and measurement of the plated film thickness

Analysis of on-site surface treatment solutions

Atomic absorption photometer

Qualitative and quantitative analysis of the metals in aqueous solution

ICP emission spectrometer

Qualitative and quantitative analysis of metals and non-metals in aqueous solution

High performance liquid chromatography

Separation and quantitative analysis of impurities in solution

Corrosion test for plating

Salt Spray Test apparatus (SST)

Corrosion resistance evaluation after surface treatment (such as plating)

Cyclic corrosion tester (CCT)

Corrosion resistance evaluation after surface treatment (such as plating)

Inquiries about YUKEN Technology

Feel free to contact us with any inquiries.